Don't miss our Full range of woodworking tools - 20% OFF! Email: ruisen@wooditool.com

Unveiling the Power of the 13-Inch Benchtop Thickness Planer

When it comes to woodworking, one essential tool that can make a significant difference in your projects is the 13-inch benchtop thickness planer. This compact yet mighty machine has the capability to transform rough lumber into perfectly flat, smooth, and uniform boards. In this blog, we’ll explore the features, benefits, and various applications of the 13-inch benchtop thickness planer, helping you unlock its potential for achieving professional-grade woodworking results.

The Mighty 13-Inch Benchtop Thickness Planer

Before we dive into the applications, let’s get familiar with the 13-inch benchtop thickness planer:

- Capacity: The “13-inch” in its name refers to the maximum width of a board it can plane. This generous capacity makes it suitable for a wide range of woodworking projects.

- Compact Design: Unlike larger floor-standing planers, benchtop models are compact and designed to fit on a workbench or any flat, stable surface. This makes them ideal for small workshops and for woodworkers with limited space.

- Two Key Functions: Thickness planers serve two primary functions: reducing the thickness of a board and ensuring that it’s perfectly flat and parallel on both sides.

- Adjustable Cutting Depth: Most benchtop thickness planers feature an adjustable cutting depth or depth-of-cut control, allowing you to remove just the right amount of material for your project.

Applications of the 13-Inch Benchtop Thickness Planer

- Dimensional Lumber Smoothing: One of the most common uses of a benchtop thickness planer is to smooth and even out dimensional lumber. It transforms rough, uneven boards into flat, smooth, and uniform pieces, making them suitable for a variety of woodworking projects.

- Custom Furniture Building: Woodworkers often use benchtop thickness planers to create custom furniture components, such as tabletops, cabinet doors, and chair seats. Achieving consistent thickness is crucial for professional results.

- Thickness Adjustment: If you need specific board thicknesses for your project, the planer allows you to tailor the boards to the exact dimensions you require.

- Reclaimed Wood Processing: For those who work with reclaimed wood, a benchtop thickness planer can remove surface imperfections, old finishes, and warp from salvaged boards, giving them new life.

- Cost Savings: By purchasing rough-sawn lumber and milling it yourself with a thickness planer, you can often save money compared to buying pre-surfaced boards.

- Trimming and Sizing: Whether you’re creating moldings, bevels, or joinery components, a benchtop thickness planer helps you achieve precise thickness and dimensions.

Selecting the Right Benchtop Thickness Planer

When choosing a 13-inch benchtop thickness planer, consider the following factors:

- Power and Speed: Look for a model with sufficient power (measured in amps) and a reasonable feed rate (measured in feet per minute) to handle your projects efficiently.

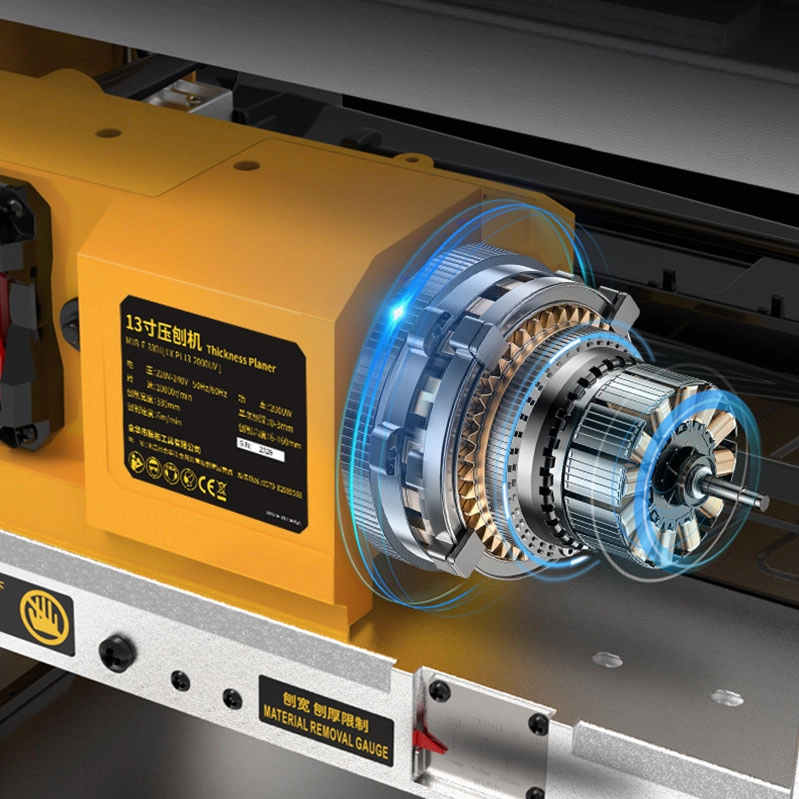

- Cutter Head: Helical cutter heads are known for producing a smoother finish and reducing tear-out compared to straight knife cutter heads.

- Dust Collection: A planer with an effective dust collection system can help keep your workspace clean and protect your health.

- Sturdy Construction: Ensure that the planer is built with durable materials to withstand the demands of woodworking.

The 13-inch benchtop thickness planer is a powerhouse in the world of woodworking, enabling precision, consistency, and versatility in your projects. Whether you’re a professional craftsman or a DIY enthusiast, this compact but robust tool can take rough lumber and turn it into beautifully flat, uniform boards. From furniture building to custom component creation and more, the benchtop thickness planer is a must-have for any woodshop, helping you achieve professional-grade results and unleashing your creativity with each pass.