Don't miss our Full range of woodworking tools - 20% OFF! Email: ruisen@wooditool.com

Mastering Precision with Woodworking Parallel Guide Rails

In the realm of woodworking, achieving precise and consistent cuts is paramount. Enter the woodworking parallel guide rail—a versatile and indispensable tool that elevates the accuracy and efficiency of your projects. In this blog, we’ll explore the features, benefits, and practical applications of parallel guide rails, guiding you through the journey of mastering precision in your woodworking endeavors, whether you’re a seasoned craftsman or a passionate DIY enthusiast.

Understanding Woodworking Parallel Guide Rails

Before we delve into the applications, let’s grasp the essence of woodworking parallel guide rails:

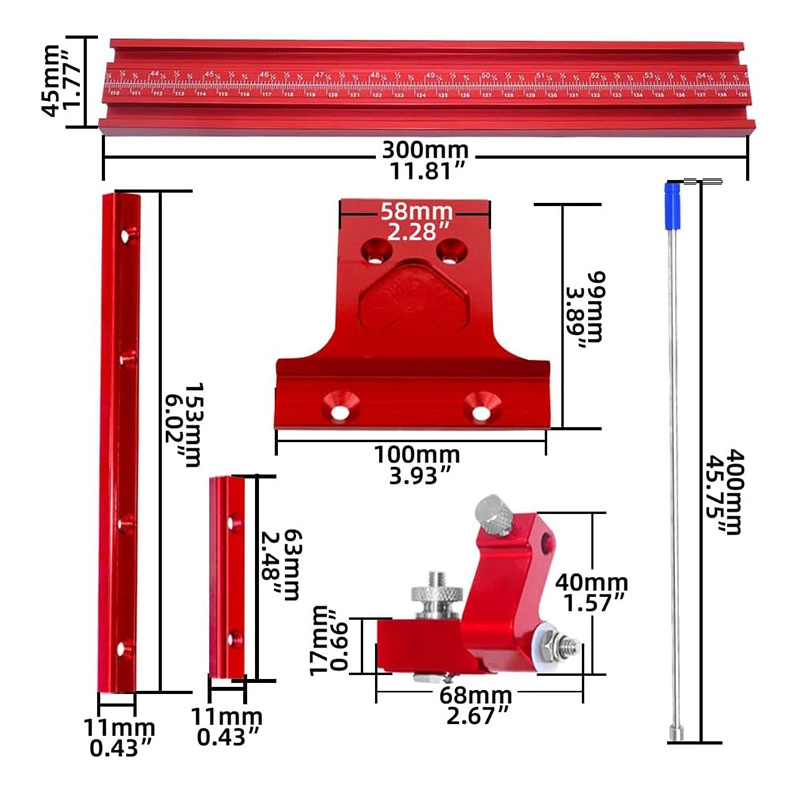

- Design and Composition: Parallel guide rails are typically made from sturdy materials like aluminum or steel. They are designed with a straight edge and a system that allows for precise adjustment and clamping.

- Adjustable Design: What sets parallel guide rails apart is their adjustable nature. Woodworkers can fine-tune the position of the guide rail to achieve parallelism with the cutting path, ensuring consistent and accurate cuts.

- Compatibility: These guide rails are often designed to be compatible with various woodworking tools, such as circular saws, routers, and jigsaws. This adaptability makes them a versatile addition to any workshop.

Applications of Woodworking Parallel Guide Rails

- Straight and Consistent Rip Cuts: The primary function of a parallel guide rail is to facilitate straight and consistent rip cuts. Whether you’re working with plywood, MDF, or solid wood, the guide rail ensures that your cuts are parallel to the edge of the workpiece.

- Repeatable Crosscuts: Achieving precise crosscuts is a breeze with parallel guide rails. Woodworkers can set the guide to the desired width and make repeatable crosscuts without the need for additional measurements.

- Dado and Groove Cutting: When creating dadoes, grooves, or rebates, a parallel guide rail provides a stable reference for the tool, resulting in clean and accurate cuts.

- Panel Sizing: Breaking down large panels into smaller, more manageable sizes is made easier with the use of parallel guide rails. This is particularly useful for cabinetmaking and other projects that involve large sheet goods.

- Router Guiding: Attach a router to the guide rail to achieve controlled and precise routing. This is especially beneficial for tasks like inlay work, edge profiling, and dado routing.

- Jigsaw Accuracy: Securely clamp the parallel guide rail to guide a jigsaw along a straight path. This is advantageous when cutting curves or intricate shapes accurately.

Selecting the Right Parallel Guide Rail

Choosing the right parallel guide rail is crucial for achieving optimal results. Consider the following factors:

- Length: Select a guide rail length that suits the size of your projects. Longer guide rails are ideal for large panels and sheets.

- Compatibility: Ensure that the guide rail is compatible with your woodworking tools, such as circular saws or routers.

- Material and Construction: Look for guide rails made from durable materials like aluminum or steel for stability and longevity.

- Adjustability: Opt for a guide rail with easy and precise adjustment mechanisms to achieve the desired parallelism.

Woodworking parallel guide rails are the key to unlocking a new level of precision and efficiency in your projects. Whether you’re making straight cuts, crosscuts, or tackling more intricate tasks like routing or dado cutting, these versatile tools provide a stable and adjustable reference for your woodworking tools. Invest in a quality guide rail that suits your needs, and witness how mastering precision becomes an integral part of your woodworking journey, transforming your creations from good to exceptional.